Steam boilers & service

Hagelschuer provides you with everything you require for reliable and energy-efficient system operation. From planning to commissioning, we’ll take care of everything that is required. Furthermore, we are also available around the clock for conversions, maintenance work or servicing.

Rental boilers and accessories

Rent

More than 100 rental boilers available at short notice

The quick and uncomplicated solution: Simply rent steam and hot water boilers, and the corresponding modules & vessels.

System construction

BUY

Individual, custom-made boiler systems

New systems for various applications, custom-made and “Made in Germany” are available here.

Service

Service

Our full service for operating your boiler system without faults

Hagelschuer is your full service provider for operating your boiler system without faults. Our specialist staff will take care of regular maintenance, required repairs and training for your employees.

Your advantages

- Energy-efficient system construction, “Made in Germany”

- Individualisation instead of assembly

- Turnkey steam generation from a single source

- All-round service, fast delivery

Your reliable partner

for boilers & service for 30 years.

Your advantages

- Energy-efficient system construction, “Made in Germany”

- Individualisation instead of assembly

- Turnkey steam generation from a single source

- All-round service, fast delivery

What our customers say

Digital

boiler log

STEAM BOILER

GOES DIGITAL

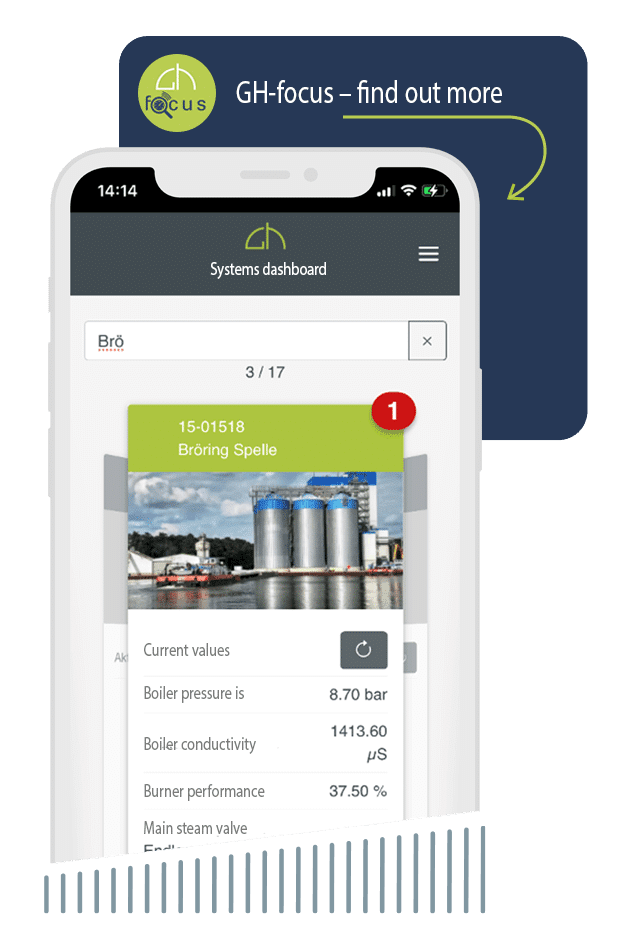

The innovative app from Hagelschuer ensures fault-free and efficient operation of your system in real time and also offers a wide range of useful functions.

GH focus

Invest in your digital future and in more reliability. GH focus is already part of many Hagelschuer rental boiler and new systems. Existing boilers can be retrofitted easily. Just ask us, we’ll be happy to help.

Digital boiler log

Record all of your system operation parameters digitally, securely and with the ability to reproduce them at any time on all end devices.

Reliability package

GH focus provides a complete function monitor for all of the system’s peripheral devices and alerts you immediately if threshold values are not reached.

Water treatment & metering

Always view current values for the water treatment operating parameters and ensure that the water chemicals are used in an environmentally friendly manner.

Areas of application

The Hagelschuer industrial boiler systems are equipped ideally for any area of application. No matter what your challenge, we will always find a solution to help you quickly and without complications. Thanks to our in-house production and our large network, we are also able to handle requests at short notice quickly. Our references in the various areas of application will provide you with an initial overview.

Current references

Current news from Georg Hagelschuer and our industry sector.

Location Dublin- Britta is drawn to the Irish capital

Britta rental boiler system (3 t/h, 2.37 MW, 16 bar) sold to partner.

Jette comes back

Jette (3 t/h, 2.1 MW, 16 bar) was in operation in the Diepholz district at an international manufacturer of sound storage media.

Two steam accumulators delivered to Poland

Hagelschuer delivered a total of three identical steam accumulators to a company in the automotive industry.