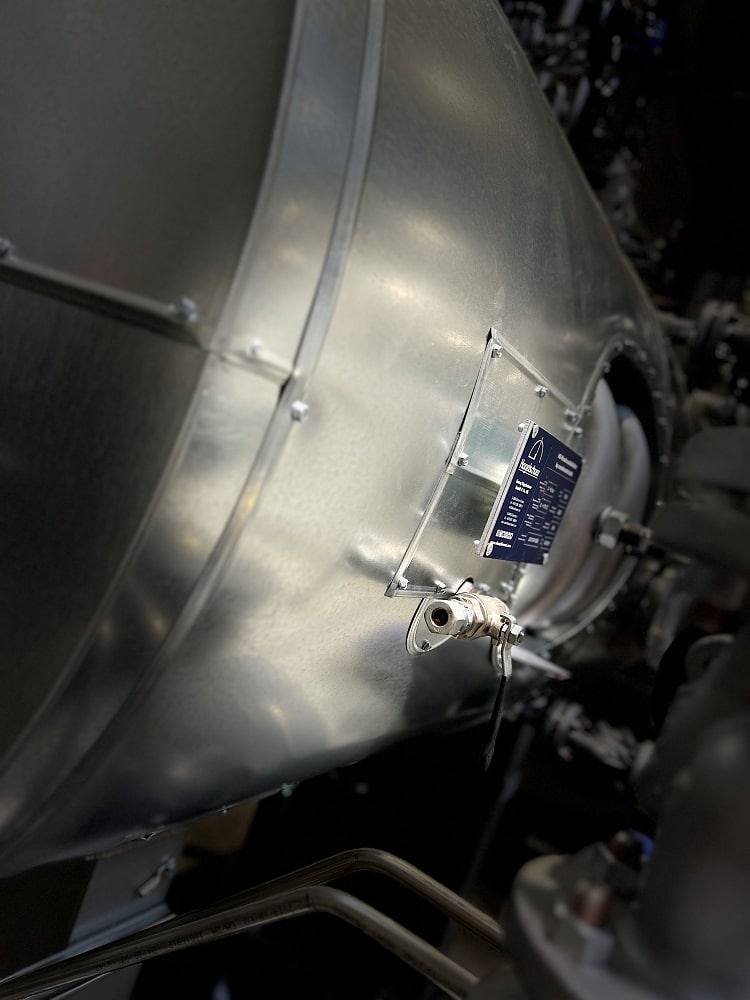

High-pressure condensate module ensures energy savings

Condensate return also available in a convenient modular design

Hagelschuer has just completed this high-pressure condensate module for a customer in the paper industry. The basic function of a high-pressure condensate module is quickly explained. The condensate produced by the steam consumers is fed into the condensate tank and collected there. It is kept at temperature and under pressure in the tank to prevent flash steam losses. The upstream pump module ensures that the condensate can be fed back into the steam boiler. It is therefore not necessary to degas the condensate again. This drastically reduces the amount of fuel, the amount of make-up water required and the use of chemical dosing agents for water treatment. High-pressure condensate systems can be used whenever the condensate parameters would result in large flash steam losses when fed into the feed water tank. However, this is not the case in all sectors, which is why this module cannot be used everywhere. Our Hagelschuer experts will be happy to advise you personally on which individual design is suitable for your system.

Further information and our direct contacts can be found here.