Steam quantity measurement

Possible areas of application and the functional principle

Precise steam quantity measurement is useful for internal energy balancing. Hagelschuer always offers its customers steam quantity measurement when purchasing a new steam boiler system. Another possible application is the temporary installation in an existing system that is to be renewed. The exact consumption values can be determined with the steam quantity measurement. This allows the new system to be designed as efficiently as possible and avoids unnecessary costs. The steam quantity measurement is then integrated into the new system. However, it also makes sense for operators of their own steam network with individual operating units or external steam consumers. This allows exact quantities to be recorded for the billing of steam and energy consumption .

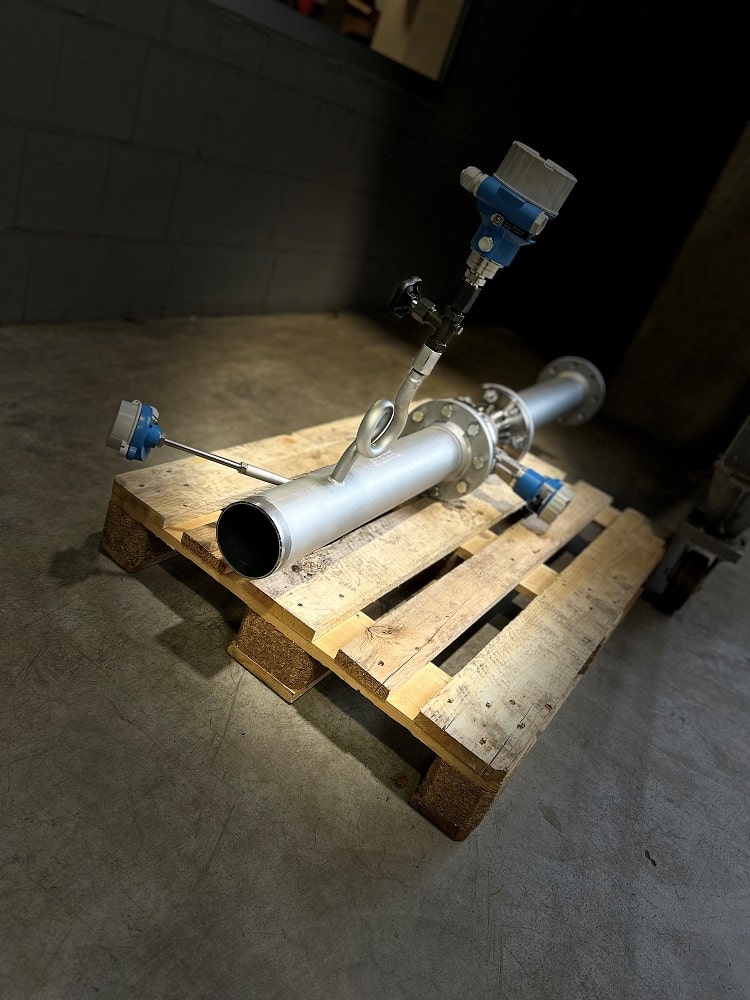

Vapor meters work on the principle of Kármán’s vortex street and are therefore also called vortex meters. In practice, the normal Flow velocity in the pipeline to the formation of vortices is often not sufficient, therefore the installation of a vortex meter reduces the Pipe cross-section. Behind the The accumulators installed in the pipeline then form alternating vertebrae with opposite direction of rotation. These vortices generate positive or negative pressure. These Differences in pressure are compensated by a mechanical sensor in the Precise steam volume measurement recorded. As the distance between two vortices always corresponds to a very specific volume, the total flow rate can be calculated using the number of vortices flowing past. Depending on the equipment, the vortex frequency flowmeters can combine different measuring systems. For example, you can measure the operating pressure, temperature and volume flow.

Our experts will be happy to take care of the correct design, calculation and installation of a steam flow meter for you!