Altonaer Wellpappenfabrik GmbH & Co KG

Case Study: Largest feasible single container module manufactured

Altona corrugated board factory relies on its own steam supply

Altonaer Wellpappenfabrik GmbH & Co. KG in Tornesch, a member of the Panther Packaging Group, is further expanding its site.

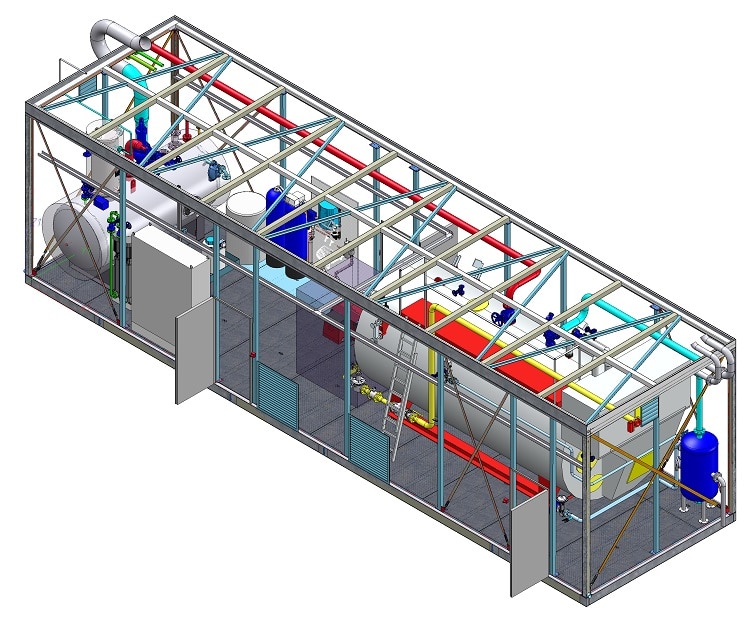

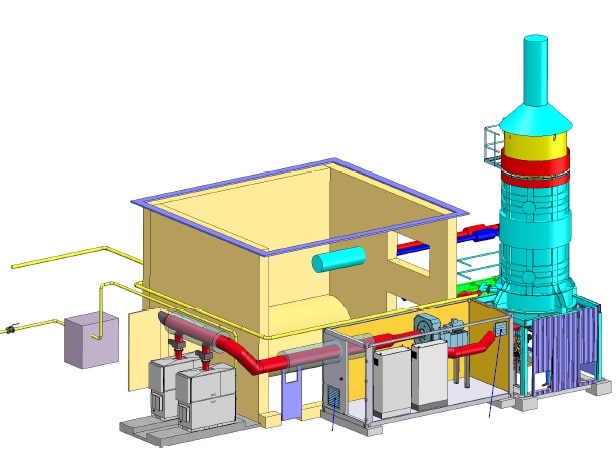

The production steam for the state-of-the-art corrugator was still provided by the neighboring paper mill until summer 2018. In the meantime, a self-sufficient mobile Hagelschuer steam boiler plant takes over the supply. The largest possible compact unit in just one GH container module measures 15 m in length, 4 m in width and it is 4.20 m high.

The task

All system-relevant components had to be housed and arranged in a very small footprint to allow for easy technical support of the system and maintenance.

The attachment

The installed steam boiler produces 8 t/h at a maximum operating pressure of 18 bar. The plant has a feedwater tank with degasser and a control cabinet with electrical distribution. The exhaust gases are discharged via the 21 m high stainless steel stack.

- GH container module

- Steam capacity 8 t/h

- 18 bar operating pressure

About Altonaer Wellpappenfabrik GmbH & Co. KG

Altonaer Wellpappenfabrik GmbH & Co. KG – theplant in the north was founded in 1902. Since 1961, the original cell of the Panther Group has been located in Tornesch (Schleswig-Holstein). Panther’s northernmost corrugated board plant supplies northern Germany and Scandinavia.

More references for steam generators in for paper production

Nestler Wellpappe GmbH & Co KG

Hagelschuer delivered the just completed GH container plant Malte (12 t /h, 8.4 MW, 26 bar) to the corrugated board mills. The rental boiler plant was specially adapted to the customer’s requirements before delivery.

PAKA Glashütter Pappen- und Kartonagenfabrik GmbH

PAKA Glashütter Pappen- und Kartonagenfabrik GmbH CASE STUDY: STEAM GENERATOR FOR PAPER AND CORRUGATED CARDBOARD COGENERATION SYSTEM FOR PAKA PAKA produces a huge range of