PAKA Glashütter Pappen- und Kartonagenfabrik GmbH

CASE STUDY: STEAM GENERATOR FOR PAPER AND CORRUGATED CARDBOARD

COGENERATION SYSTEM FOR PAKA

PAKA produces a huge range of cardboards for a wide range of applications in Glashütte in Saxony.

The task

The company commissioned Hagelschuer to plan and implement an individual cogeneration system to heat up the thermal oil.

The system

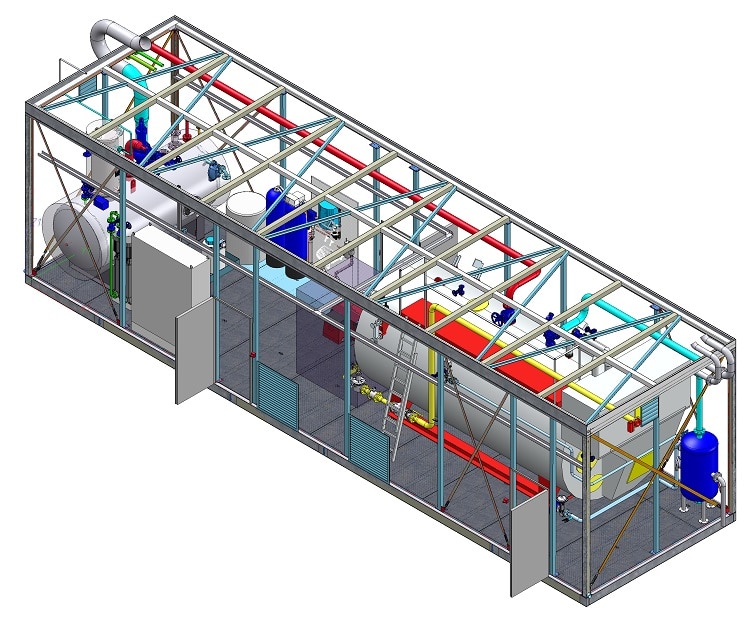

The system is used to reheat the flue gases from two turbines. The thermal oil is essential for producing paper and cardboard. The steam generator for paper and corrugated cardboard was set up in a sea container and has an output of 3.5 MW. In addition to the actual cogeneration system, Hagelschuer planned, produced, supplied and installed the entire flue gas and waste gas pipelines.

- Set up in a sea container

- Output of 3.5 MW

- Ultra-modern system technology

About PAKA Glashütter Pappen- und Kartonagenfabrik GmbH

PAKA Glashütter Pappen- und Kartonagenfabrik GmbH has been producing mill board for more than 130 years. Numerous products for applications in many industrial branches are produced on two systems.

Further references for steam generators for paper production

Nestler Wellpappe GmbH & Co KG

Hagelschuer delivered the just completed GH container plant Malte (12 t /h, 8.4 MW, 26 bar) to the corrugated board mills. The rental boiler plant was specially adapted to the customer’s requirements before delivery.

Altonaer Wellpappenfabrik GmbH & Co KG

Altonaer Wellpappenfabrik GmbH & Co KG Case Study: Largest feasible single container module manufactured Altona corrugated board factory relies on its own steam supply Altonaer