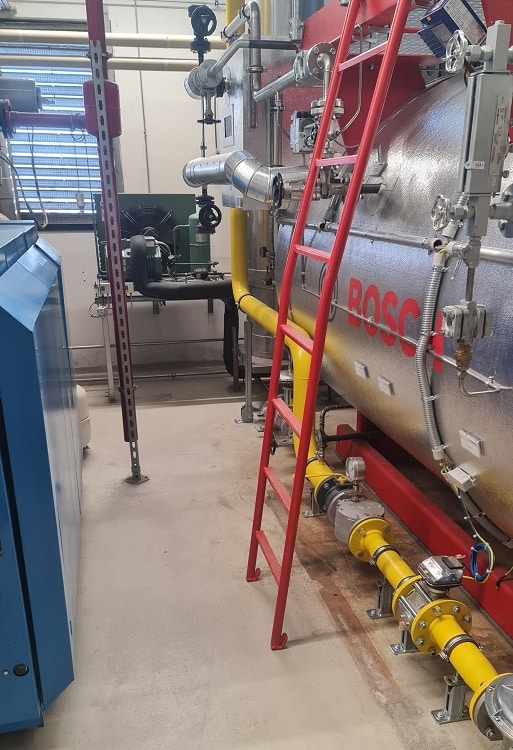

2 t/h steam generator as product boiler

Easier installation conditions ensure the desired boiler location in production

One of the largest bakery companies in the world, needed a new steam boiler plant for its production site in the Harz Mountains. In order to existing infrastructure and connection to the consumer further to maintain, the new steam boiler plant had to be reinstalled in the installation room on the 1st floor. Since this according to applicable federal law no longer complied with the regulation for: “Technical Rules for Steam Boiler Installation – Installation of Steam Boiler Plants with Group IV Steam Boilers (TRD 403)”, an approvable solution for the new plant had to be found.

The task

The Hagelschuer experts were able to quickly remedy this situation by taking advantage of the simplified installation conditions for the product boilers. For this purpose the simple basic formula of pressure x water content < 20,000 applied. In this specific case, this meant: the boiler with NW 2.56 m³ may have a maximum pressure of 7.5 bar so that the 20000 is not exceeded. Here the plant can be equipped with 6.5 bar working pressure on the existing line system are driven and is thus significantly below the max. permissible operating pressure.

The attachment

In addition to the 2 t/ 6.5 bar steam boiler , the plant includes a new switchgear, a new burner, an economizer, a 1500 l feedwater tank with degasser and feed pumps. A complete water treatment incl. residual hardness control unit and dosing was also installed. In addition, a new condensate monitoring system has been integrated to ensure maximum safety from contaminated condensate. The flue gas continues to be discharged via the existing element stack, and the existing infrastructure was also used for the fuel supply. The on-site installation was carried out without any disruptions during ongoing operation. This impressed the customer so lastingly that he gave it extra praise.

- 2 t/ 6.5 bar Steam boiler

- 1500 l feed water tank with degasser and feed pumps

- Water treatment incl. residual hardness control unit and dosing

- condensate monitoring for maximum safety

More references for steam generators in the food industry

Hybrid steam boiler delivered to AVO Werke

Project managers at AVO Werke in Belm relied on Hagelschuer for the planning.

Plant delivered with two steam boiler bodies in hybrid design.

Project partner mediates Jule before completion

Our rental boiler plant Jule (3 t/h, 2.1 MW, 16 bar) had not yet been completed when we received the first inquiry from our project partner CAL Trading from the Netherlands. A dairy plant for goat milk needs an additional process steam supply as a temporary solution for approx. 2 years for the expansion of its product range. The customer’s requirements were high; in addition to a fully equipped container facility, the customer also wanted the ongoing operating costs to be as low as possible.

Deutsche See GmbH

Hagelschuer was commissioned to manufacture a new 2 t/h steam boiler system with 10 bar. The system was designed as a compact, fully functional mobile unit in a special container.

Rent boiler Julius sold

Rent boiler Julius sold The rental boiler Julius became a sold GH container plant Julius (3 t/h, 2.1 MW, 16 bar) was actually intended to

Harries Mühle

Harries Schälmühlenwerk GmbH & Co KG Harries Mühle – mobile energy center delivered as GH container plant Hagelschuer delivered a new fully equipped GH container

SchapfenMühle

SchapfenMühle GH container plant installed on the roof as an energy center The tradition-conscious family business SchapfenMühle has a high quality awareness and demanding requirements