Aryzta

Delivery capability of the Aryzta plant in Eisleben ensured

Rent boiler Iris as an emergency helper

With a real “quick shot”, Hagelschuer was able to secure the delivery capability of the Eisleben plant of the Aryzta company. There, the failure of a heat exchanger with thermal oil (800 kg/h at 0.8 bar) had caused production bottlenecks. Hagelschuer implemented a replacement solution with the “Iris” rental boiler in just four days.

The task

At noon on Tuesday, the emergency call from Eisleben reached the Hagelschuer headquarters in Buldern. On the same day, the “Iris” 1,250 kg/h saturated steam boiler, as a compact unit with hose lines up to DN32 0.5-1.2 bar pressure reducer, could be offered as a solution. The order was placed on Wednesday morning. Hagelschuer started immediately with the conversion of the pressure reducer to the required downstream pressure.

The attachment

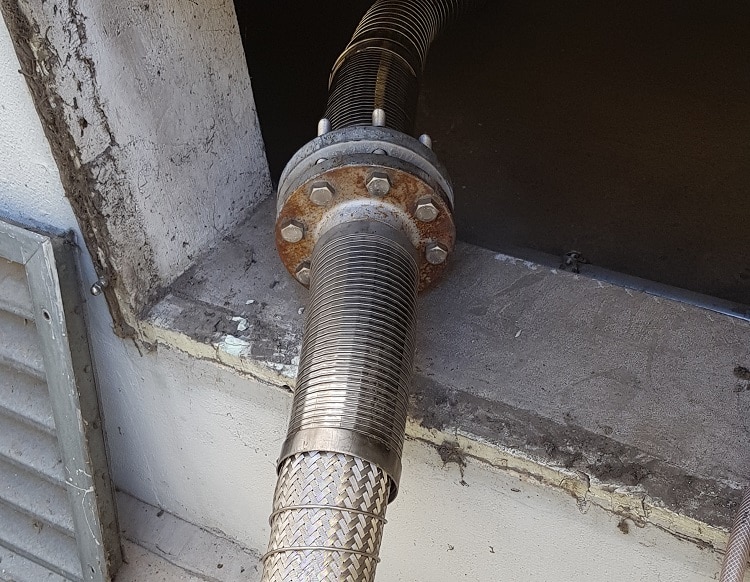

On the same day, Iriswas loaded together with 30 m of DN 80 steam hoses and a 5 m³ fuel oil tank. On Thursday, “Iris” and its peripherals arrived in Eisleben, where they were assembled and refueled with fuel oil.

On Friday, the TÜV inspection and commissioning took place. Exactly four days after the emergency call, reliable steam supply for production was restored.

- Pressure reducer DN32 0,5-1,2 bar

- 30 m steam hoses DN 80

- 5 m³ fuel oil tank

Thomas Hinrichs Project Manager Hiestand Deutschland GmbH

“Out of three companies we chose Hagelschuer, our requirements were met. We focus on operational safety and energy efficiency. Hagelschuer is a reliable partner.”

More references for steam generators in the food industry

Hybrid steam boiler delivered to AVO Werke

Project managers at AVO Werke in Belm relied on Hagelschuer for the planning.

Plant delivered with two steam boiler bodies in hybrid design.

2 t/h steam generator as product boiler

Hagelschuer lays out 2 t/h steam generator as so-called product boiler

Easier installation conditions ensure the customer the desired boiler location in production.

Project partner mediates Jule before completion

Our rental boiler plant Jule (3 t/h, 2.1 MW, 16 bar) had not yet been completed when we received the first inquiry from our project partner CAL Trading from the Netherlands. A dairy plant for goat milk needs an additional process steam supply as a temporary solution for approx. 2 years for the expansion of its product range. The customer’s requirements were high; in addition to a fully equipped container facility, the customer also wanted the ongoing operating costs to be as low as possible.

Deutsche See GmbH

Hagelschuer was commissioned to manufacture a new 2 t/h steam boiler system with 10 bar. The system was designed as a compact, fully functional mobile unit in a special container.

Rent boiler Julius sold

Rent boiler Julius sold The rental boiler Julius became a sold GH container plant Julius (3 t/h, 2.1 MW, 16 bar) was actually intended to

Harries Mühle

Harries Schälmühlenwerk GmbH & Co KG Harries Mühle – mobile energy center delivered as GH container plant Hagelschuer delivered a new fully equipped GH container