Franken Bräu

HIGH CUBE CONTAINER CONVERTED INTO BOILER HOUSE

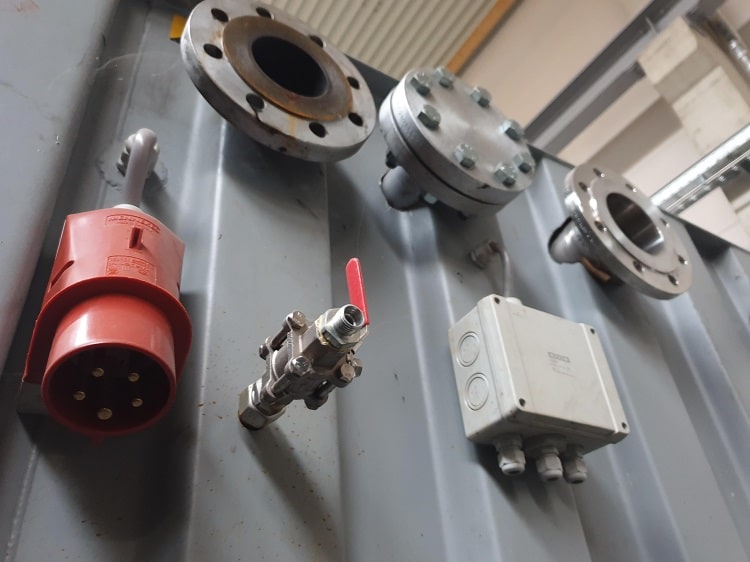

For this purpose, the shell boiler was placed in a newly constructed High Cube container with transport dimensions of 9.30 x 2.65 x 3.05 m. The container is equipped with a special water heater. In addition, all the plant components required for operation were arranged in the container and installed in accordance with regulations. Thus, this compact plant can be installed directly at the customer’s site without any further construction measures and can be put into operation immediately.

The task

His first use of the rental boiler with the name “Sören” was at the well-known traditional brewery Franken Bräu. With 600 kg steam per hour at 9 bar operating pressure expanded Hagelschuer Rhine Main thus its rental offer. Through the compact design and the low weight, the plant is particularly suitable for the rapid deployment and is relatively easy to transport.

Mr. Rainer Mohr Managing Director and owner of Franken Bräu Holding GmbH about Hagelschuer as a project partner:

The company Georg Hagelschuer was quickly decided for us. Within three days, they had delivered the system to us, set it up and made it ready for operation. With the steam boiler we were able to supply our plant with the necessary operating pressure, so we were still able to deliver our goods bottled in time to the Schützenfest in Kronach. Hagelschuer was not only a competent partner, but also

quick rescuer in an emergency.

Other references for steam generators in the food industry

Hybrid steam boiler delivered to AVO Werke

Project managers at AVO Werke in Belm relied on Hagelschuer for the planning.

Plant delivered with two steam boiler bodies in hybrid design.

2 t/h steam generator as product boiler

Hagelschuer lays out 2 t/h steam generator as so-called product boiler

Easier installation conditions ensure the customer the desired boiler location in production.

Project partner mediates Jule before completion

Our rental boiler plant Jule (3 t/h, 2.1 MW, 16 bar) had not yet been completed when we received the first inquiry from our project partner CAL Trading from the Netherlands. A dairy plant for goat milk needs an additional process steam supply as a temporary solution for approx. 2 years for the expansion of its product range. The customer’s requirements were high; in addition to a fully equipped container facility, the customer also wanted the ongoing operating costs to be as low as possible.

Deutsche See GmbH

Hagelschuer was commissioned to manufacture a new 2 t/h steam boiler system with 10 bar. The system was designed as a compact, fully functional mobile unit in a special container.

Rent boiler Julius sold

Rent boiler Julius sold The rental boiler Julius became a sold GH container plant Julius (3 t/h, 2.1 MW, 16 bar) was actually intended to

Harries Mühle

Harries Schälmühlenwerk GmbH & Co KG Harries Mühle – mobile energy center delivered as GH container plant Hagelschuer delivered a new fully equipped GH container