Conditorei Coppenrath & Wiese

STEAM GENERATOR FOR HIGH PRODUCTION CAPACITIES

Conditorei Coppenrath & Wiese started on a comprehensive programme of investment together with the Oetker Group in 2017. This included expanding the location in Mettingen including new steam generators for the food industry.

The task

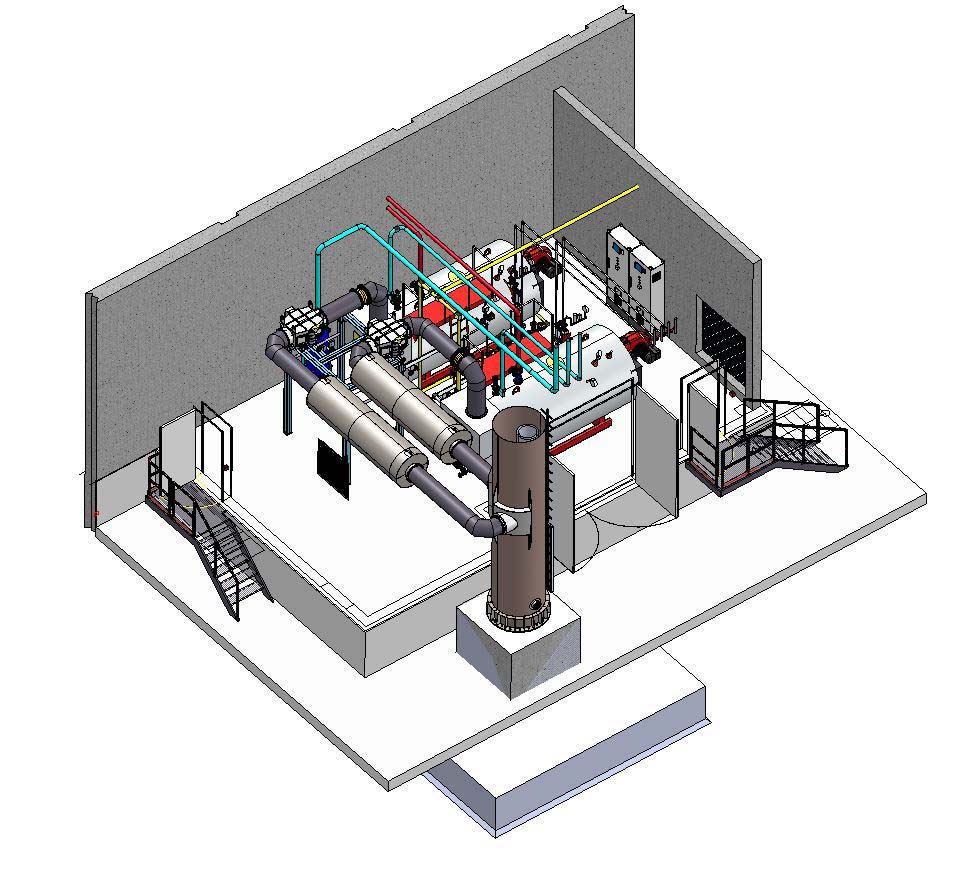

A completely new boiler house was erected to increase production capacities. The new steam boiler system moved in at the end of July 2020. Hagelschuer supplied a system that complies with the Technical Instructions on Air Quality Control and noise protection emissions. An existing feed water treatment system that was large enough was integrated into the new system equipment without problems. There is therefore enough saturated steam available to expand the production capacities.

The system

The system comprises two 3.2 t/h steam boilers, each with 10 bar operating pressure, which are fired with ultra-modern NOx-reduced burners. In order to comply with the requirements of the Technical Instructions on Air Quality Control and noise protection emissions, both boilers were equipped with flue gas condensers among other things. The main function of the flue gas condensers is to cool the flue gases. The flue gas vapours are around 118 degrees and are cooled to 80 degrees Celsius. The water used fort the cooling process heats up automatically and is used for other production processes that occur.

The cooled flue gases are then guided through the silencers that are each around 4 m long. This reduces the noise output by 30 decibels before the flue gases are guided through the almost 30 m high stack in accordance with the regulations.

- Two 3.2 t/h steam boilers

- Flue gas condensers to cool the flue gases

- Silencer reduces the noise by 30 dB

About Conditorei Coppenrath & Wiese

The company is headquartered in Metting and was founded in 1975. It manufactures frozen baked goods. The range includes tortes, cakes, desserts and bread rolls. The company has been part of the Dr. Oetker Group since 2015.

Further references for steam generators in the food industry

Hybrid steam boiler delivered to AVO Werke

Project managers at AVO Werke in Belm relied on Hagelschuer for the planning.

Plant delivered with two steam boiler bodies in hybrid design.

2 t/h steam generator as product boiler

Hagelschuer lays out 2 t/h steam generator as so-called product boiler

Easier installation conditions ensure the customer the desired boiler location in production.

Project partner mediates Jule before completion

Our rental boiler plant Jule (3 t/h, 2.1 MW, 16 bar) had not yet been completed when we received the first inquiry from our project partner CAL Trading from the Netherlands. A dairy plant for goat milk needs an additional process steam supply as a temporary solution for approx. 2 years for the expansion of its product range. The customer’s requirements were high; in addition to a fully equipped container facility, the customer also wanted the ongoing operating costs to be as low as possible.

Deutsche See GmbH

Hagelschuer was commissioned to manufacture a new 2 t/h steam boiler system with 10 bar. The system was designed as a compact, fully functional mobile unit in a special container.

Rent boiler Julius sold

Rent boiler Julius sold The rental boiler Julius became a sold GH container plant Julius (3 t/h, 2.1 MW, 16 bar) was actually intended to

Harries Mühle

Harries Schälmühlenwerk GmbH & Co KG Harries Mühle – mobile energy center delivered as GH container plant Hagelschuer delivered a new fully equipped GH container