Potts Brewery

NEW CHP PLANT FOR BREWERY POTTS

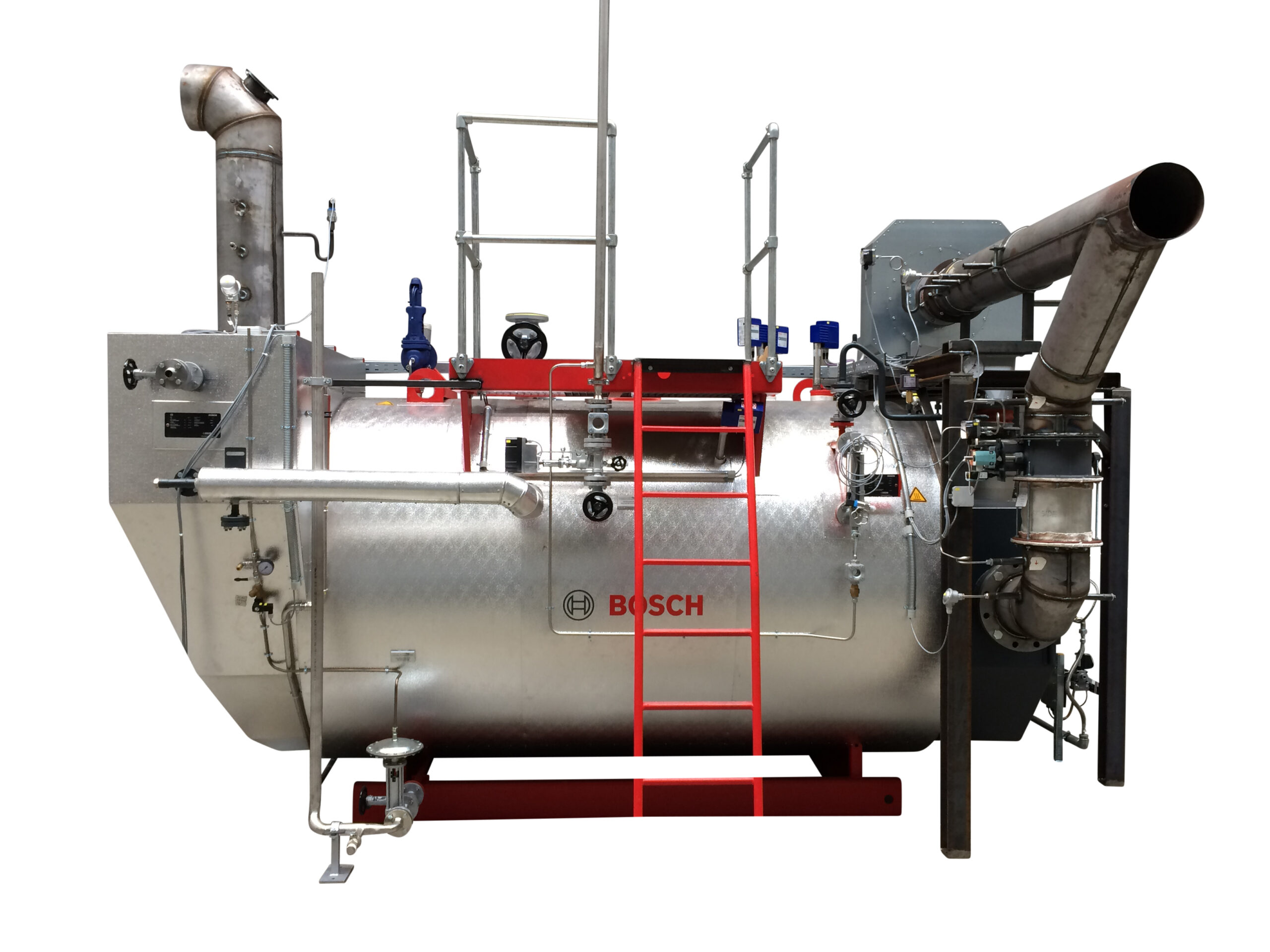

For the Oelde-based specialty brewery Pott’s, Hagelschuer, together with the engineering office Hebmüller, took over the planning and implementation of a steam generator. This can be used in combination with a micro gas turbine as a CHP plant.

The task

A Capstone microturbine was used to generate electricity and thermal power. The exhaust gas heat is used directly by feeding the 300 °C hot exhaust air with 17.5% residual oxygen content to a steam boiler (2 t saturated steam/h at 4 bar overpressure) as primary combustion air. The steam thus generated is used for the brewhouse and for heating the hot water network.

The attachment

The new CHP plant at Pott’s is characterized by significantly lower fuel consumption compared to conventional plants. Thanks to the extremely compact and space-saving modular design, the oldhistoric steam engine could be preserved as a technical monument in its original location.

- 2 t saturated steam/h at 4 bar overpressure

- Capstone micro gas turbine

- lower fuel consumption

About Brewery Potts in Oelde

The traditional brewery Pott’s has existed since 1769 and is now run by the 7th generation of the family. The core of the company’s philosophy is its strong ties to the region. The beer specialties are characterized by their naturalness and a long, frosty maturation. Pott’s beers are brewed with a lot of passion and craftsmanship. This is reflected in the quality.

Other references for steam generators in the food industry

Hybrid steam boiler delivered to AVO Werke

Project managers at AVO Werke in Belm relied on Hagelschuer for the planning.

Plant delivered with two steam boiler bodies in hybrid design.

2 t/h steam generator as product boiler

Hagelschuer lays out 2 t/h steam generator as so-called product boiler

Easier installation conditions ensure the customer the desired boiler location in production.

Project partner mediates Jule before completion

Our rental boiler plant Jule (3 t/h, 2.1 MW, 16 bar) had not yet been completed when we received the first inquiry from our project partner CAL Trading from the Netherlands. A dairy plant for goat milk needs an additional process steam supply as a temporary solution for approx. 2 years for the expansion of its product range. The customer’s requirements were high; in addition to a fully equipped container facility, the customer also wanted the ongoing operating costs to be as low as possible.

Deutsche See GmbH

Hagelschuer was commissioned to manufacture a new 2 t/h steam boiler system with 10 bar. The system was designed as a compact, fully functional mobile unit in a special container.

Rent boiler Julius sold

Rent boiler Julius sold The rental boiler Julius became a sold GH container plant Julius (3 t/h, 2.1 MW, 16 bar) was actually intended to

Harries Mühle

Harries Schälmühlenwerk GmbH & Co KG Harries Mühle – mobile energy center delivered as GH container plant Hagelschuer delivered a new fully equipped GH container